Rubber Molding/Rubber hose - Quick turn, custom molded parts in as fast as 1-25 days. Rubber Hose/ Molding Companies

2023年3月30日星期四

Fuel line hose SIZE

2023年3月28日星期二

EPDM material applications for Grommets and Gaskets

EPDM, or ethylene-propylene-diene monomer is a type of synthetic rubber that is used in many applications.

When choosing a material to use for rubber grommets or gaskets, many people opt for standard materials such as neoprene or silicone since they are readily available. While these materials may perform as desired for some applications, EPDM offers many favorable features and advantages when compared to other materials, making it an ideal grommet and gasket material.

EPDM Grades

EPDM gaskets are manufactured from solid, sponge, or foam rubber materials. Each type of material has a unique molecular structure enabling EPDM gaskets to possess physical properties, such as hardness and chemical resistance, to meet the specifications of many applications. EPDM are categorized by grades such as commercial, peroxide-cured, UL 94 flame-retardant, and FDA-approved.

EPDM Grommet and Gasket Material Properties

Ethylene and propylene are both hydrocarbons that remain in gaseous states at room temperature. When combined, they create polymers such as polyethylene and polypropylene, which remain solid. By controlling the polymerization process and adding the proper proportion of ethylene and propylene, it is possible to create EPDM.

The process of manufacturing EPDM creates long molecular chains that give the material its enhanced elastic properties. EPDM is unique among elastomers because it remains flexible at very low temperatures and can be formulated to withstand extremely high temperatures. The material is also resistant to oxidation and the aging effects of ultraviolet light.

EPDM possesses superior mechanical properties. It has a tensile strength ranging from 7 to 21 MPa, making it stronger than silicone, which has a tensile strength of 5 and 10 APa; nitrile, which is between 12 and 15 MPa; and neoprene, which is between 5 and 8 MPa.

EPDM rubber grommets and EPDM rubber gaskets are more resistant to wear from abrasion and are formulated to resist harsh chemicals such as acids and alkalis. EPDM material is ideal for applications involving auto wiring grommets. It’s stability and heat-resistant properties also make it suitable for applications using steam.EPDM rubber grommets/gaskets offer a variety of benefits when compared to other rubber materials. They can withstand harsh environmental conditions and are designed to provide reliable, long-lasting sealing capabilities over a wide range of temperatures from -60° F to 300° F.

EPDM grommets/gaskets offer good electrical insulation and are highly resistant to wear, ultraviolet light, aging, wind, weather, and ozone. They are also color-stable and won’t stain mating surfaces.

EPDM Gasket Applications

EPDM is a strong, durable, and cost-effective option that offers superior performance for use in many applications, including:

1)Outdoor. Since EPDM gaskets are able to withstand extreme temperature fluctuations, water, and UV rays, they are ideal for use in outdoor applications.

2)Electrical. The material’s high electrical resistance makes EPDM grommets or EPDM gaskets suitable for many electrical installations.

3)Open Joints. EPDM grommets and EPDM gaskets have a good compression set resistance, which allows for easy recovery, making it appropriate for applications where a joint may open up occasionally.

Contact Us About Your EPDM Grommet,Gasket & Seal Needs

At Custom Grommets and Gaskets Manufacturing, we specialize in manufacturing precision molded EPDM rubber parts including grommets and gaskets and seals for various industries and applications. Our commitment to outstanding quality and customer service has earned us a reputation throughout the world as an industry leader. To request a quote or learn more about EPDM grommets and EPDM gaskets, contact us today :sales@rubberbiz.com or mobile:86-13720889256

2023年3月24日星期五

Rubber bellows production process

We have over 19 years experience in manufacturing Rubber Bellows /Rubber parts ,and mass production bellows applications. Clients within industries such as Automotive, Aerospace, Marine and Manufacturing choose to work with us to ensure their rubber bellows are provided to the highest of standards. We manufacture rubber bellows using a broad range of rubbers and silicones to meet customer requirements.

Please check the rubber bellows production process as following video:

2023年3月23日星期四

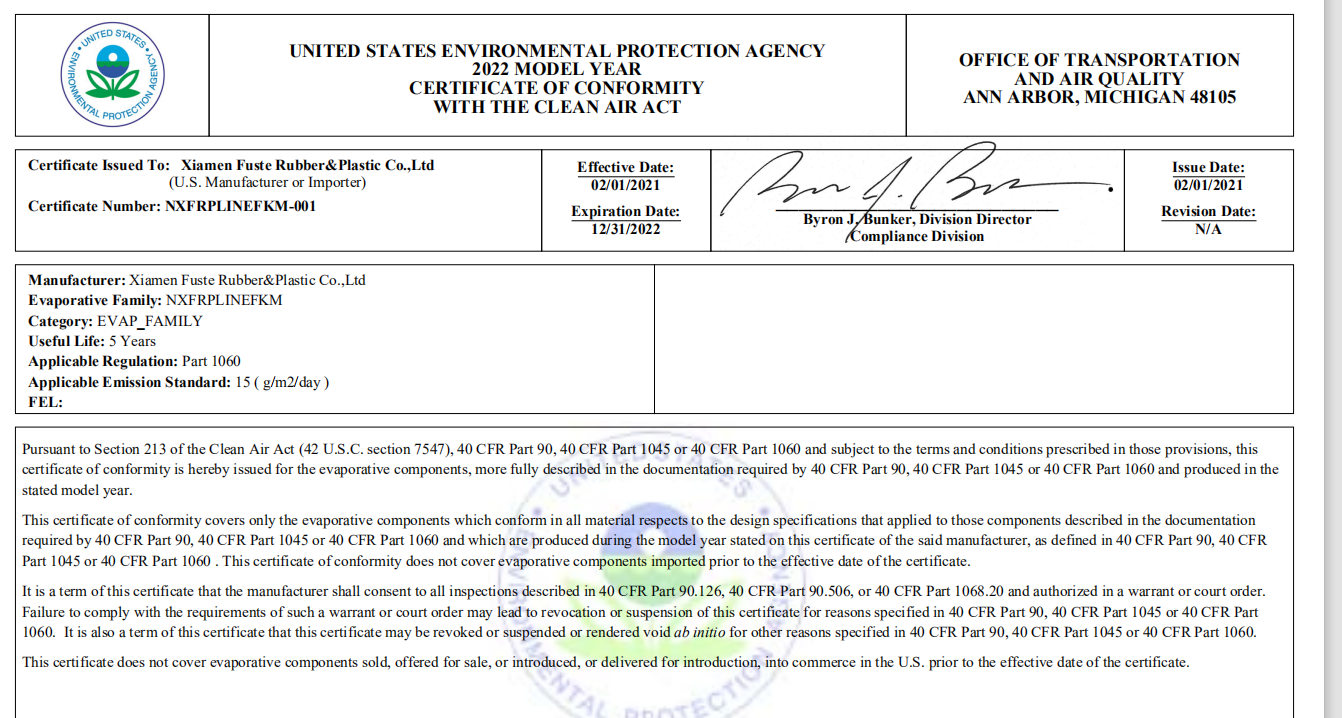

CARB EPA Fuel Line Hose Introduction

Here I will introduce the fuel line hose producted by our factory.Our CARB/EPA Fuel hose include 2 -layer hose(FKM/ECO)and 4-layer hose(FKM/ECO/Aramid/ECO).

The following specifications are commonly produced in our factory:

1)FKM/ECO hose(ID*OD): 4mm*8mm, 5mm*9mm, 6mm*10mm.

2)FKM/ECO/Aramid/ECO hose(ID*OD): 6.35mm*12.7mm, 7.94mm*14.3mm, 9.53mm*15.88mm, 12.7mm*19.84mm

We also have other dimensions.If you need, you can also send dimensions and quantity to me and we can customize them.

Our Fuel hose has passed EPA and CARB certifications.Welcome you to inquire for customization.

Any questions,please feel free to contact us via sales@rubberbiz.com.

2023年3月21日星期二

Molds for Injection Rubber Molding

In order to successfully use injection molding, you will need the right rubber mold.

Molds are created through two processes: Computer Numerical Control machines (CNC) and Electric Discharge Machines (EDM).

CNC machines use cutting tools to cut into a piece of material. If a rubber manufacturer wants to use a plastic mold, it could use a CNC machine to create that mold. When dimensions are inputted into the CNC machine, they cut away the piece of material until it fits the dimensions. Some CNC machines are also equipped with laser printing which is another way for rubber manufacturers to create molds.

Electrical Discharge Machines are similar to CNC machines. Instead of cutting, these machines use electric “lasers” to remove parts of the material. When dimensions are entered into the machine, it goes straight to work creating the mold. EDM is typically used for more complicated molds that may require curved edges and specialized shapes.

If you are looking for a rubber molding company that provides both standard and custom rubber parts, we can help. Xiamen Fuste Rubber offers molded rubber parts that you need. Here are some of our incredible features:

1)Hands-on customer service and engineering team

2)High-quality materials

3)Thousands of prefabricated parts

4)Custom parts in any color, size, function or shape

5)Enhanced durability and safety

6)National and international shipping

7)ISO certified to ensure quality and high standards

Let's start cooperation from here ,Please do not hesitate to contact me by sales@rubberbiz.com .